OSMOSTAR uses the technologies of reverse osmosis and electrodeionization for produsing purified water. The system is compact, easy operating and quick installed.

|

Infeed Water temperature: – Operation – Design |

15-25°C 15-25°C |

|

Infeed Water Flow: – Operation – Design |

on request |

|

Output Water Flow: – Normal – Design |

on request |

|

Chemicals Concentration: NaCLO H202 NaOH NaHSO3 |

3-5% 3% 1% 1% |

|

Incoming Power: – Controls – Motors |

380VAC/3phase/50Hz |

|

Nameplate Power: – Controls – Motors |

220VAC/50Hz and 24VDC 380VAC/3phase /50Hz |

|

Location |

indoor |

|

Ambient Air Temperature: – Design Minimum – Design Maximum |

Winter 10°C 10 °C 35°C |

|

Area Classification |

Unclassified Non-hazardous |

|

Noise Level |

<85dB as sound Pressure level |

|

Pressure Vessel Design Standard |

GB150-1998 |

|

Piping Design Standard |

ANSI |

|

Skid Material |

Stainless steel 304 |

|

Enclosure nameplate material |

Stainless steel 304 |

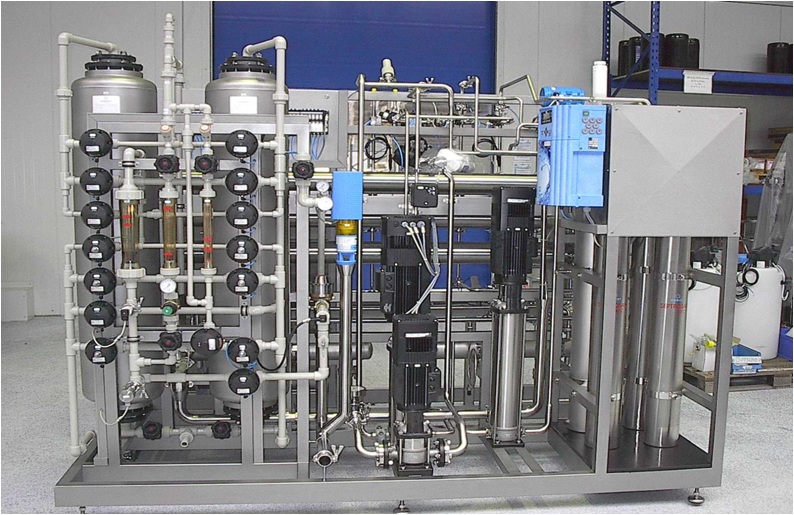

- Technical data of purified water generator

2.1. Water conversion factor (WCF)

WCF of pretreatment – about 97%

WCF of 1’st RO – about 75%

WCF of EDI – about 90%

WCF of All – 70%

2.2. Size of skid

Each skid will be installed in individual frame including interconnected pipe and cable.

The size of skid will be provided on request

MMF+ACF

Softener

OSMOSTAR+EDI

2.3. Utility consumption

Raw water

Capacity 11.5 -13 m3/h

Pressure 2-3 bar,

Temperature 15-35℃

Electric power

Voltage 415VAC Phase 3P

Power 15 KW

Oil free compressed air

Flux 0.1Nm3/hr

Pressure 6-7 bar

- Output: 500 l/hour – 50000 l/hour.

- Water pre-preparation: removes low molecular weight organics.

- Water softening system: Ca and Mg filtration stage

- Filter 5 µm: removal of the bulk of the incoming particles > 5 µm

- Reverse Osmosis System: removes most of salts, TOC, endotoxins and SiO

- Deionizations modulesfull removal Co, Cl, and SiO

- Central control and monitoring system: full automatic control and on-line monitoring.